MicroEpsilon surfaceControl3D¶

The image source integrates surfaceControl3D sensors from MicroEpsilon. The image source can be operated either as a range image source or as a 2D grayscale image source. Both modes require their own image acquisition. In range mode, the source delivers 2.5D data as a range image. In Intensity mode, the source supplies an 8 gray-scale image (image 2 per Master-Slave image sources) from each of the two cameras.

Installation and configuration¶

Warning

The Micro-Epsilon SDK uses the GigE driver of the Pleora eBUS SDK for sensor communication. The Cognex GigE-Vision driver uses the same SDK in a potentially different version. Before installing the device software, the Cognex GigE-Vision driver may need to be removed.

In vision projects with Surface-Control 3D Sensor no Cognex CogAcqFifo image source can be used and vice versa!

Warning

Pleora names some network cards that may be incompatible or provide poor performance. See Pleora Support Center

The necessary Pleora eBUS SDK is automatically installed together with Micro-Epsilon_3D-View or Micro-Epsilon_3DInspect.

For the network card which is used to connect the SurfaceControl3D image source, the eBUS Universal Pro For Ethernet Driver must be activated. Pleora also recommends to adjust the following settings on the network card if possible (see Pleora Support Center):

jumbo packets / jumbo frames: “activate” [maximum]

Receive buffers / receive descriptors: “increase” [maximum]

interrupt moderation rate / interrupt throttling: “experiment” [maximum rate, no throttling]

turn off to save energy: switch off (in the configuration of the network adapter in the Energy management tab)

Image source settings¶

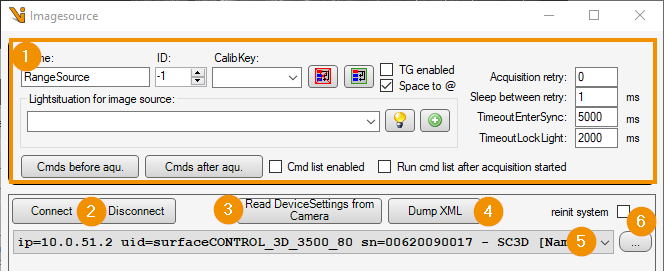

General¶

Generic settings, see image-sources editor

Connect / Disconnect: Triggers a manual connection attempt to the sensor or disconnects the connection. If the connection is disconnected, an automatic connection attempt is made when the image is captured.

Read device settings from camera: Reads the current sensor settings and transfers them to the image source.

Dump XML: Writes all sensor settings to an XML file.

Device: Sensor hardware to which the image source refers. Connected devices can be selected from the drop-down list.

…: Updates the list of available devices. If reinit system is activated, the MEGC system is completely reinitialized before searching for devices. All connected devices are disconnected!

Acquisition¶

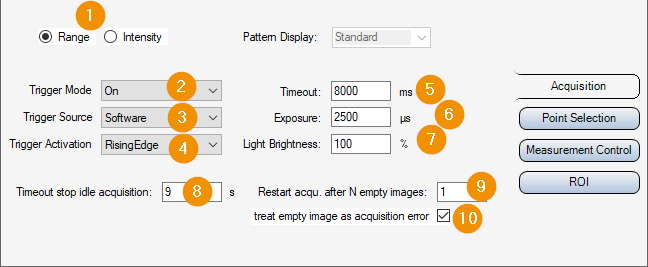

Range / Intensity: Switching the image source mode: 3D data or camera images feed.

Trigger Mode / -Source / -Activation: Selection of the signal source for starting an image capture. If Trigger Mode is switched off, the device continuously captures images. The image source then delivers the next incoming image after the start of image capture. Otherwise, the defined event triggers the image capture. A software trigger may be generated by the image source.

Timeout: Time limit for image acquisition (excluding possible TimeoutEnterSync waiting times). The image acquisition is canceled after expiry.

Exposure: Exposure time for image capture. In Range mode, repeated exposures are made and the time is multiplied accordingly.

Light brightness: Brightness of the built-in projector. It is recommended to set this to 100% as long as the exposure time can be shortened.

Patter Display: Pattern of the projector when illuminated in Intensity mode.

Timeout stop idle acquisition: Timeout that restarts with each image acquisition. If no further image acquisition takes place within the specified time, the image acquisition of the device is stopped. For example, the projector can be switched off in Intensity mode. -1 deactivates the timeout, the image capture loop of the sensor then runs potentially indefinitely. The value must always be set higher than the image acquisition timeout, otherwise an ongoing image acquisition may be terminated prematurely.

Hint

Switching parameter sets considerably extends the duration of the image acquisition. If a toolgroup requires both range and intensity images or images from the same sensor with different settings, a sequential image acquisition can be activated for the job to avoid errors when selecting suitable timeouts.

If the image capture is repeated with identical settings, the image capture loop of the sensor is only started once. Occasionally, the sensor appears to enter an error state in which it only delivers empty range images. The following parameters can be used to remedy such errors:

Restart acqu. after N empty images: Forces a restart of the sensor image acquisition after the specified number of empty images has been reached in immediately consecutive image acquisitions. Values <0 deactivate the function. If set to 0, a restart is forced with every image acquisition. A restart extends the duration of the image acquisition.

treat empty image as acquisition error: If active, an image acquisition error is triggered after receiving an empty image.

Hint

Simultaneously activating treat empty image as acquisition error , setting Restart acqu. after N empty image =1 and Acquisition Retry>=1 causes the image acquisition to be repeated immediately with a restart in the event of an empty image. In this way, empty images can be avoided without extending the regular image acquisition time.

Point Selection¶

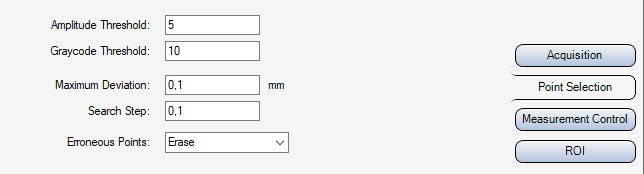

The tab summarizes GeniCam parameters that define the creation and selection of measuring points in range mode.

Amplitude Threshold: Minimum pattern contrast in the sine images

Graycode Threshold: Minimum contrast in the graycode images

Maximum Deviation: Maximum deviation of a calculated 3D point from the start value (point cloud according to Graycode)

Search Step: Step size for the search in the Z range

Erroneous points: Method for handling erroneous points, for example when exceeding MaximumDeviation

Measurement Control¶

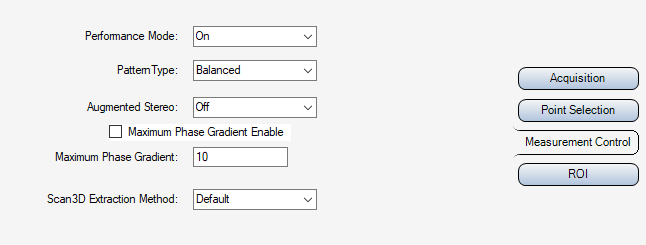

Performance Mode: Accelerates data processing at the expense of increased sensor temperature

PatternType: Type of projection pattern

Augmented stereo: When deactivated, only points that are perceived by both sensor-internal cameras are included in the output. Occlusions can be reduced by activating this option. However, this can make interfering points visible. When using it, it is recommended to activate the Maximum Phase Gradient for outlier suppression.

Maximum Phase Gradient Enable: Enables/disables the Maximum Phase Gradient threshold.

Maximum phase gradient: Threshold value for sorting out outliers in the 3D point cloud.

Scan3D Extraction Method: Selects the method for extracting points from the raw sensor data.

ROI¶

When operating the image source in range mode, the sensor only provides data in the area of the defined volume of interest. The volume is defined by a 2D region of interest and limit values for the depth range (Sensor3D Z coordinate). The sensor only provides points that lie within the measurement volume.

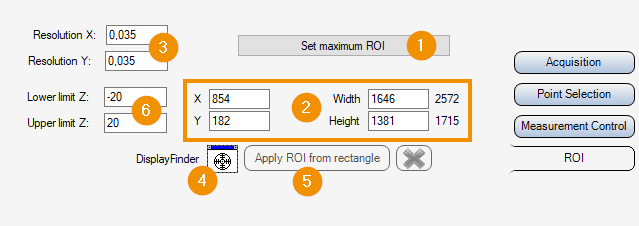

Click on Set maximum ROI (1) to set the largest possible volume.

The offset of the 2D ROI (2) refers to the maximum possible image field. Width and height indicate the dimensions of the output image. The physical size of an image pixel in the x or y direction is specified by the respective resolution (3). The ROI image section can be adjusted interactively in a display after an image with the current ROI has been captured: By dragging the Display Finder crosshair (4) onto a display, the ROI is shown there as an interactive rectangle, which can be adjusted. Then click on Apply ROI from rectangle (5) to adopt the parameters of the rectangle as the new ROI.

Upper and Lower limit Z (6) define threshold values for the measuring range. The thresholds refer to the Sensor3D coordinate space. Possible points outside of this are rejected by the sensor.

Plugin settings¶

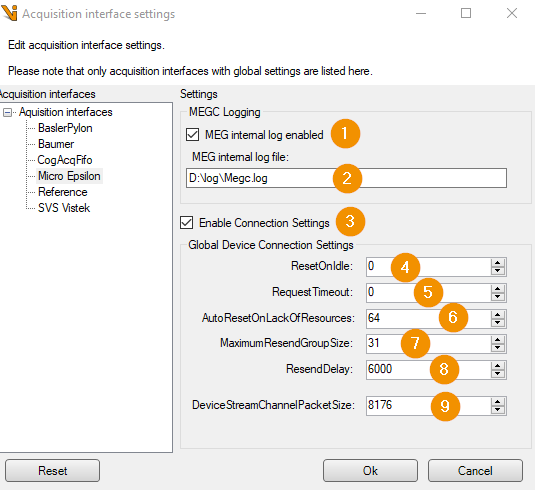

In the Advanced settings of the Vision plugin some parameters can be adjusted across devices:

MEG internal log enaled: Activates the internal logging of the MicroEpsilon SDK. The log entries appear in the image source log data. The option always uses the maximum log level of the SDK.

MEG internal log file: Optionally, a file path for saving the MicroEpsilon SDK logs can be specified. Only the MEGC internal logs are then written there. The entries continue to appear in the image source log. If the field is empty, no file is created.

Warning

The internal log file of the MicroEpsilon SDK does not follow the log4net logging configuration. The file size could possibly grow indefinitely!

Enable Connection Settings: Activates the setting of connection parameters for communication with the sensor. The settings can be used in particular to improve the communication behavior in the event of network faults. The parameters are not saved persistently by either the SDK or the sensor (with the exception of DeviceStreamChannelPacketSize). After a sensor restart, the device is therefore always operated with default parameters if the option is not activated.

Hint

If network errors occur, such as TOO_MANY_COSECUTIVE_RESENDS, these appear in the MEG internal log. As long as no errors occur, the Connection Settings do not need to be adjusted. The meaning of error messages and parameters can be found in the Pleora eBUS SDK. (see Pleora Knowledgebase)